Micro Fulfillment Centers

Automated Micro Fulfillment Centers (MFC) are standardized solutions for urban areas featuring comparably rapid installation times and lower investments. Their benefits include high storage density, rapid processing of online orders and increased customer satisfaction thanks. Micro fulfillment Centers are popular in e-commerce and food retail industry as an alternative to manual fulfillment and offer major competitive advantages in terms of last mile and delivery costs. Our MFC are scalable and easily adapted to changing market conditions.

Micro Fulfillment Centers

Automated Micro Fulfillment Centers (MFC) are standardized solutions for urban areas featuring comparably rapid installation times and lower investments. Their benefits include high storage density, rapid processing of online orders and increased customer satisfaction thanks. Micro fulfillment Centers are popular in e-commerce and food retail industry as an alternative to manual fulfillment and offer major competitive advantages in terms of last mile and delivery costs. Our MFC are scalable and easily adapted to changing market conditions.

Mini Load

Mini Load automated storage and retrieval systems (ASRS) are designed to maximize vertical storage space while maintaining a compact footprint. A high-speed Storage/Retrieval (S/R) machine moves loads safely and accurately to support the high-volume order picking operations. The Mini Load provides the ideal solution for space-saving storage of small items in cartons, totes and trays and ensures timely inventory supply for order-picking. Its modular design facilitates flexible integration of the equipment to the specific storage requirements.

Mini Load

Mini Load automated storage and retrieval systems (ASRS) are designed to maximize vertical storage space while maintaining a compact footprint. A high-speed Storage/Retrieval (S/R) machine moves loads safely and accurately to support the high-volume order picking operations. The Mini Load provides the ideal solution for space-saving storage of small items in cartons, totes and trays and ensures timely inventory supply for order-picking. Its modular design facilitates flexible integration of the equipment to the specific storage requirements.

Shuttles

The Shuttle securely stores containers, cartons and trays with loads of up to 50 kilograms. They effectively integrate important processes and applications such as picking, buffering, sequencing of goods as well as supplying workstations. Thanks to its flexible and scalable design, the Shuttle adapts perfectly to the different requirements and investment needs and can be integrated with other conveying and picking technologies, making the system the ideal solution for automating online retail or omni-channel distribution.

Shuttles

The Shuttle securely stores containers, cartons and trays with loads of up to 50 kilograms. They effectively integrate important processes and applications such as picking, buffering, sequencing of goods as well as supplying workstations. Thanks to its flexible and scalable design, the Shuttle adapts perfectly to the different requirements and investment needs and can be integrated with other conveying and picking technologies, making the system the ideal solution for automating online retail or omni-channel distribution.

Robotic Systems

Leveraging leading edge technologies, robotic solutions offer a flexible, high performance approach that can tackle sophisticated operations, remove bottlenecks and flex to accommodate industry market growth and product changes. AEDLER Robotic Systems grip items of various sizes, weights and shapes including items with different types of surfaces and packaging. These systems are designed for product extensibility that allows for easier programming and addition of new robotic capabilities or functions.

Robotic Systems

Leveraging leading edge technologies, robotic solutions offer a flexible, high performance approach that can tackle sophisticated operations, remove bottlenecks and flex to accommodate industry market growth and product changes. AEDLER Robotic Systems grip items of various sizes, weights and shapes including items with different types of surfaces and packaging. These systems are designed for product extensibility that allows for easier programming and addition of new robotic capabilities or functions.

Autonomous Mobile Robots

Autonomous Mobile Robots (AMRs) excel at safely and consistently transporting products in distribution operations. AMRs provide a more flexible and reliable alternative to conventional material transport methods involving fork trucks and static conveyors. Our AMRs systems are a cost-effective solution that reduce production and labor costs and increase efficiency, improve working conditions and easily scale to match your growth. This technology is currently used in complex functions such as sortation and order fulfillment.

Autonomous Mobile Robots

Autonomous Mobile Robots (AMRs) excel at safely and consistently transporting products in distribution operations. AMRs provide a more flexible and reliable alternative to conventional material transport methods involving fork trucks and static conveyors. Our AMRs systems are a cost-effective solution that reduce production and labor costs and increase efficiency, improve working conditions and easily scale to match your growth. This technology is currently used in complex functions such as sortation and order fulfillment.

Sortation

Designed for versatility, conveyor sortation help arrange products from multiple infeed lines adding efficiency in distribution operations. Various conveyor technology such as tilt tray, activated roller belts, cross belt sorters and narrow belt sorters seamlessly maintain product flow for further sorting, scanning or fulfillment processes. AEDLER offers a full range of proven solutions for reliable and cost-effective sorting of unit loads like cartons, parcels and containers. Our advanced systems ensure that conveyed goods arrive exactly where they should.

Sortation

Designed for versatility, conveyor sortation help arrange products from multiple infeed lines adding efficiency in distribution operations. Various conveyor technology such as tilt tray, activated roller belts, cross belt sorters and narrow belt sorters seamlessly maintain product flow for further sorting, scanning or fulfillment processes. AEDLER offers a full range of proven solutions for reliable and cost-effective sorting of unit loads like cartons, parcels and containers. Our advanced systems ensure that conveyed goods arrive exactly where they should.

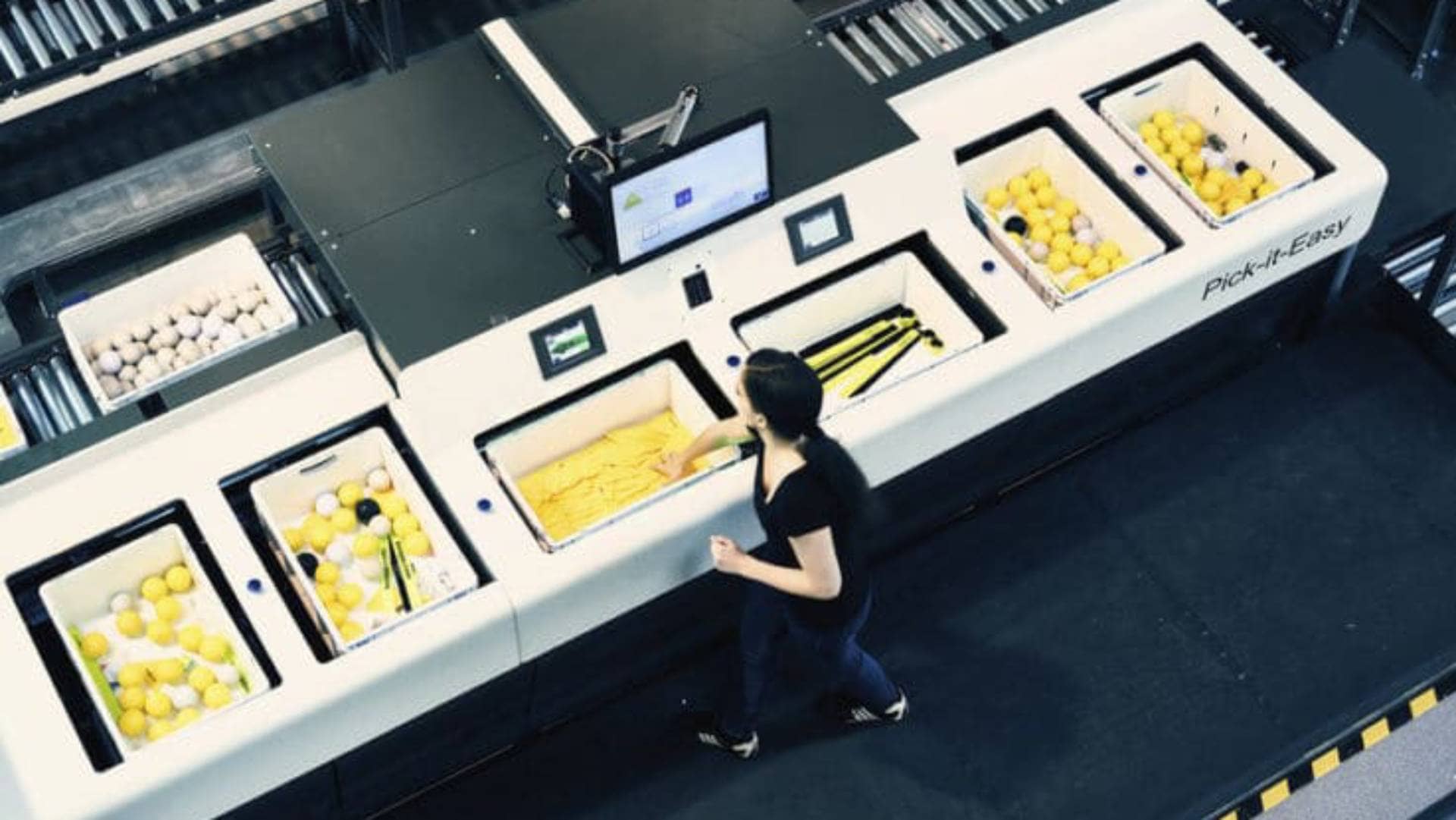

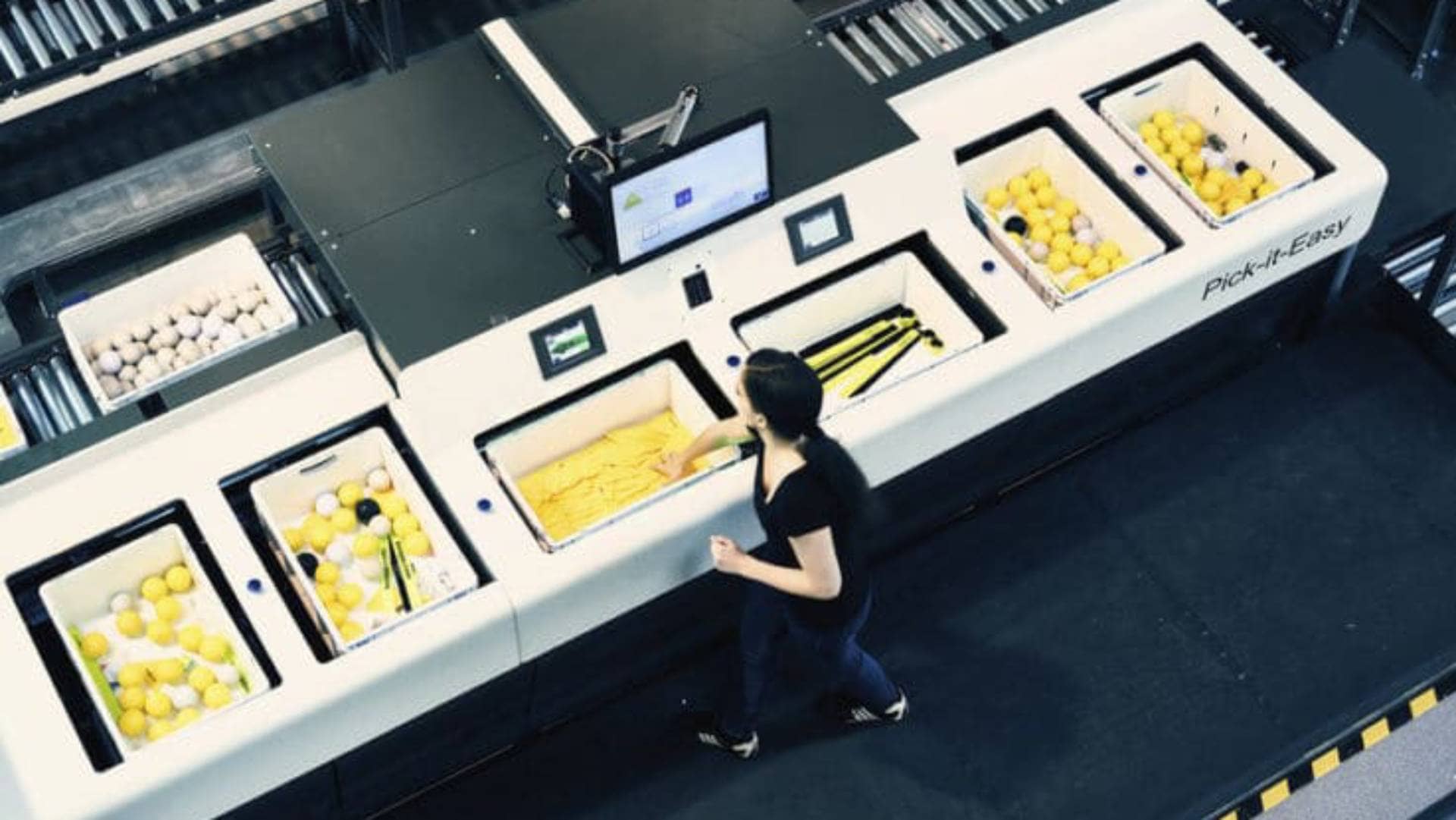

Workstations

Workstations are designed to provide the best possible work environment and manual processes in an industrial setting. AEDLER Workstations stand for efficient, error-free manual order processing and optimal ergonomics. Various tasks can be handled at the workstations, including order picking, returns processing, inventory, repacking, consolidating goods or value-added services. Our workstations create a modern work environment and increase performance, quality, and employee satisfaction.

Workstations

Workstations are designed to provide the best possible work environment and manual processes in an industrial setting. AEDLER Workstations stand for efficient, error-free manual order processing and optimal ergonomics. Various tasks can be handled at the workstations, including order picking, returns processing, inventory, repacking, consolidating goods or value-added services. Our workstations create a modern work environment and increase performance, quality, and employee satisfaction.

Pocket Sorters

The Pocket Sorter is ideal for applications in e-commerce and omnichannel fulfillment. By using overhead space, this proven technology lower costs, increases performance, and makes better use of warehouse space. Our pocket sorter systems can handle both flat-packed and hanging goods and are equipped with RFID technology, ensuring 100% traceability and accuracy. Our flexible, scalable, and sustainable intralogistics solutions evolve with your business, adapting effortlessly to shifting product ranges and growing demand.

Pocket Sorters

The Pocket Sorter is ideal for applications in e-commerce and omnichannel fulfillment. By using overhead space, this proven technology lower costs, increases performance, and makes better use of warehouse space. Our pocket sorter systems can handle both flat-packed and hanging goods and are equipped with RFID technology, ensuring 100% traceability and accuracy. Our flexible, scalable, and sustainable intralogistics solutions evolve with your business, adapting effortlessly to shifting product ranges and growing demand.