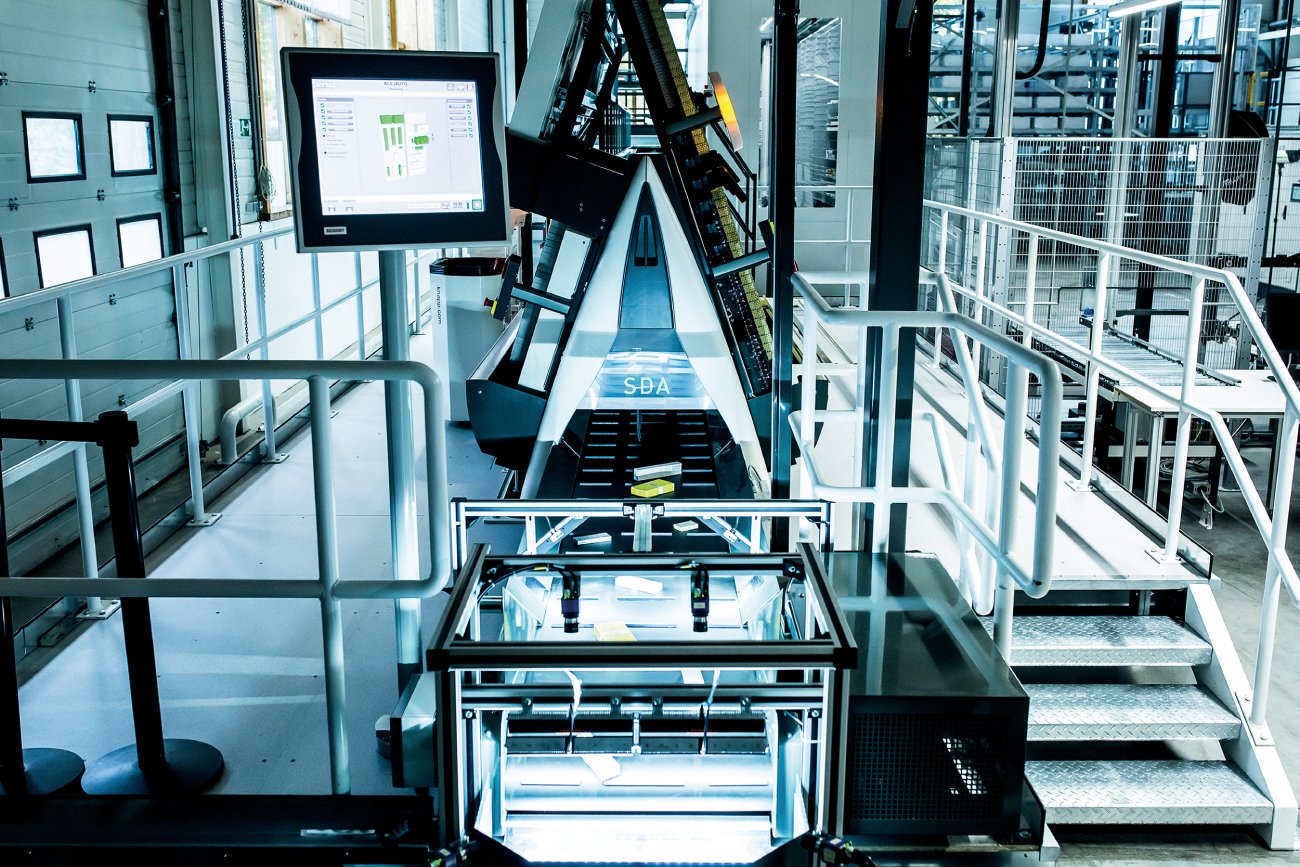

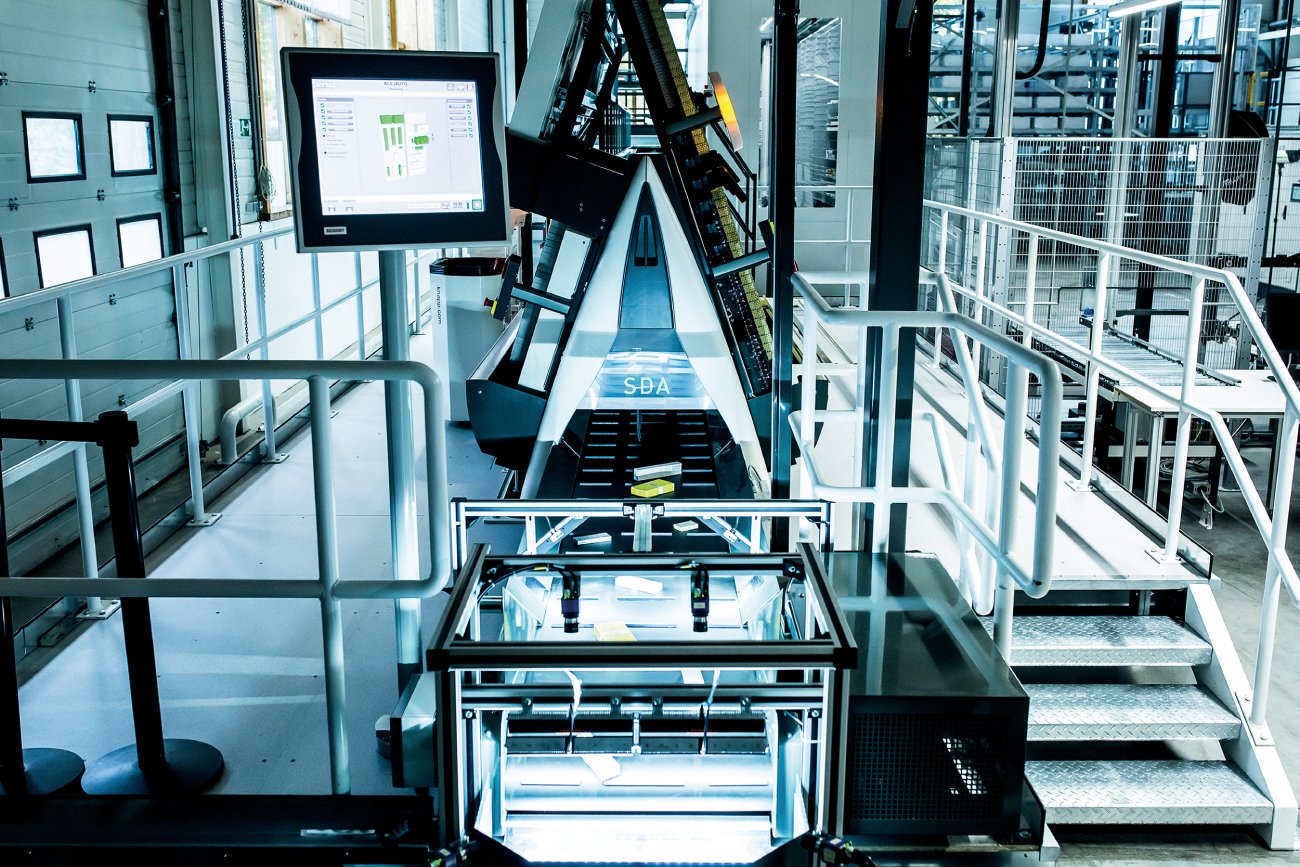

A-Frames

This fully automated system enhances material flow while reducing order transit times and increasing accuracy and reliability. Medicines are filled into the product channels and automatically separated, collected and deposited in the order container. For pharmaceutical distributors this means optimum personnel utilization in the warehouse, low error rates and a significantly enhanced performance, all in a relatively small space. AEDLER A-Frames mitigate the effects of peak workloads, make efficient use of the off-peak periods and allow important resources to be put to best use.

Robotic Picking

The robotic piece picking grips items of various sizes, weights and shapes including items with different types of surface and packaging: from round and cylindrical items to bottles and polybags with transparent surfaces. Thanks to its versatility, AEDLER cutting-edge Robotic Arms can be used in a number of different industries such as e-commerce, food retail, electronics, cosmetics, fashion and pharma. Machine Learning enables the robot to learn continuously while picking and provide reliable 24/7 operations that reduce labor costs and provides a fast return of the investment.

Shuttles

The Shuttle securely stores various sizes of containers, cartons and trays with loads of up to 50 kilograms. They effectively integrate important processes and applications such as picking, buffering, sequencing of goods as well as supplying workstations. Our Shuttle system is used for picking in many industries such as the automotive industry, pharmaceutical wholesaling, online retail, food retail, fashion and micro fulfillment. Thanks to its flexible and scalable design, the OSR Shuttle adapts perfectly to the different requirements and can be integrated with other picking and conveying technologies.

Pharma Stores

The Pharma Store is an innovative system for storing and picking single items. It covers everything from automated goods-in and space-effective storage to automated processes and stock management, all while keeping investment and storage location costs low. Our cutting-edge gripping technology allows the storage of round, cylindrical and cellophane wrapped packages. The Pharma Store is especially suitable for use in pharmaceutical wholesale and online pharmacies, providing the highest storage density where space is limited

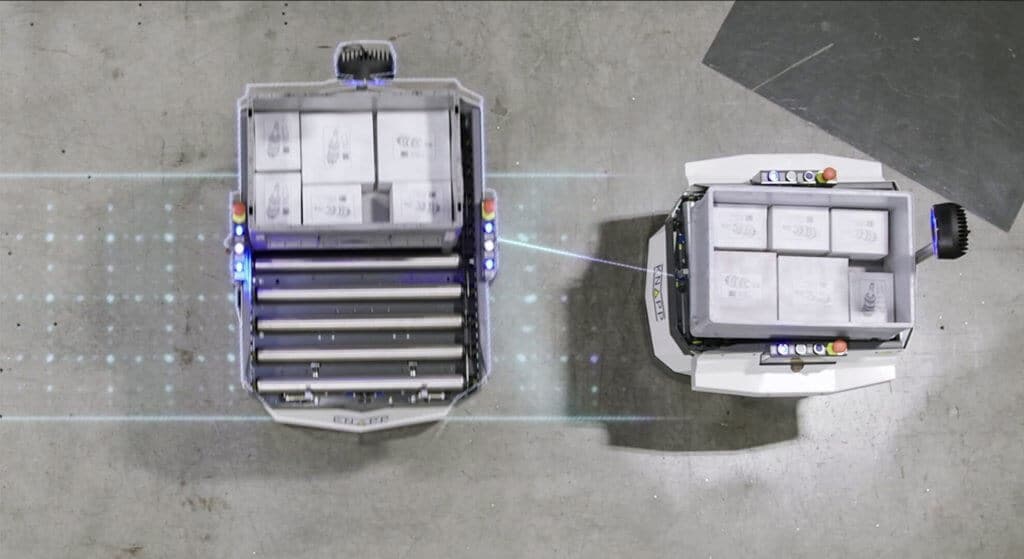

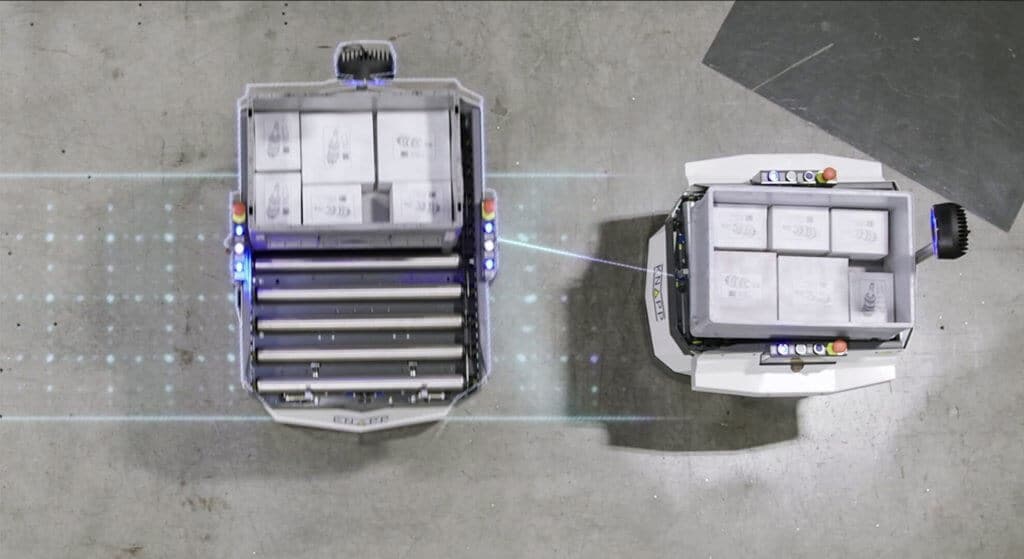

Autonomous Mobile Robots

Autonomous Mobile Robots (AMRs), reliably carry out transport orders autonomously, navigating warehouse space freely while identifying and avoiding obstacles. AMR systems offer maximum flexibility while increasing productivity and freeing up human resources for value-generating tasks. AEDLER Autonomous Mobile Robots are a smart and flexible way to automate warehouse material flow and a good alternative to stationary container and pallet conveyors. Our robots are quick and easy to integrate and can be carried out while your warehouse is in operation.

Pick-to-Light

Pick-to-light systems provide paperless fulfillment with easy-to-read lights and displays for improved productivity, speed and accuracy. These scalable systems include tray designs to accurately handle a wide variety of product sizes and shapes and require minimal training while increasing picking and accuracy. AEDLER Pick-to-light systems are equipped with sensors that automatically warn the operator in case of error and allow several operators to work on the same order. These systems increase the number of orders per day, reducing the operational cost of order picking processes.

Voice Picking

Voice picking systems are a paperless order picking solution designed for warehouses with a large number of product SKUs and require a low number of reaches per unit. Easy-to-understand voice guides operators to locations and instructs them to what task needs to be performed. Voice picking is a practical tool for picking operations as it allows the operator’s hands and eyes to be free for the task at hand. Its fast integration and low training time makes it a cost-effective option that can generate high accuracy rates.

Put-to-Light

In a Put-to-Light system, the displays visually guide the operator to the containers in which to put the articles that make up each order. Each location assigned to an order has an associated luminous display. After identifying an item, the displays visually shows the operator the locations to be put and the quantity for each order. Put-to-Light is a good solution for picking small items and leads to an increase in the number of orders picked per day and a reduction in operating costs in employees due to the short learning period.