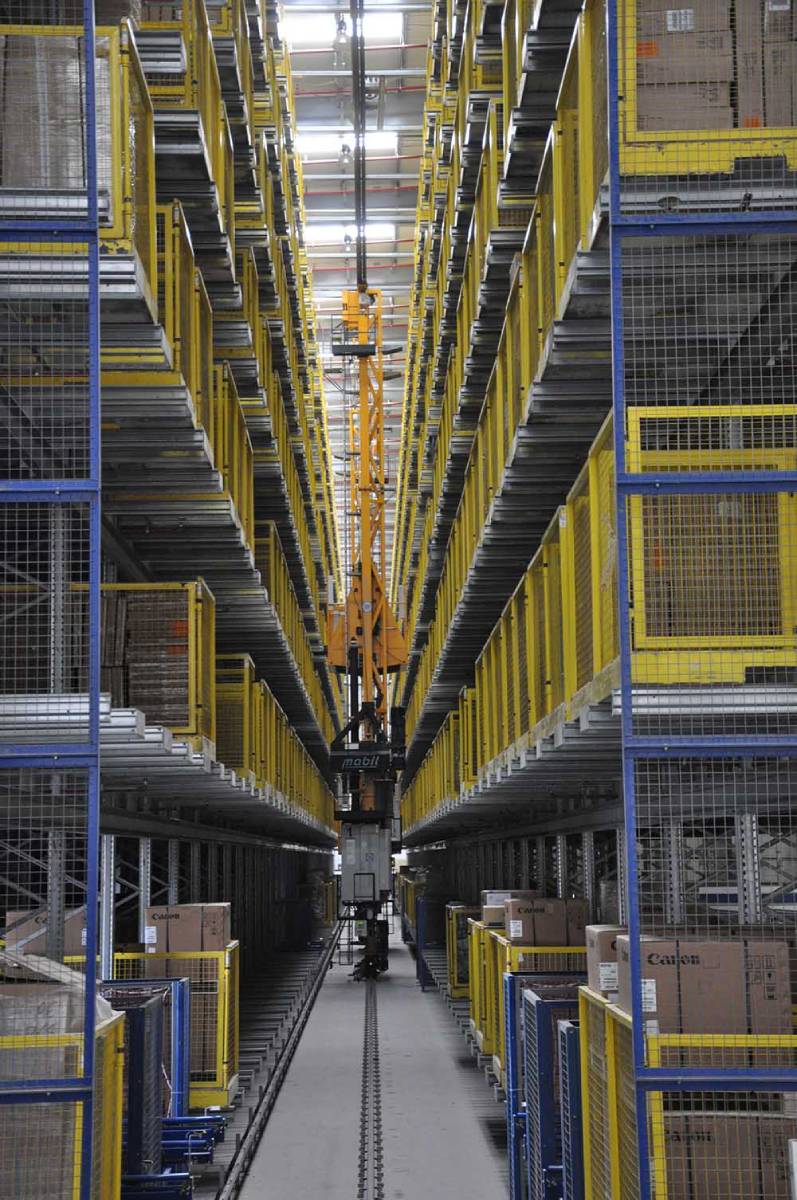

Elevating Transfer Vehicles (ETV)

These advanced Elevating Transfer Vehicles (ETV) are designed keeping in mind the utmost Storage and Retrieval of and Air Cargo Pallets and ULDs. The Inventory Control System guides all the vehicle movements with the possibility of operator overturn manual (self) mode. Built on a central rail system, the Elevating Transfer Vehicle (ETV) is located in the middle of the high-bay storage aisles along with an uplifting platform that is designed for a variety of 10, 15 and 20 ft powered roller decks with an operator cabin. From storing, transferring, storing and retrieving the cargo from the cargo and airside is automated fully alongwith interfaces to the airline and WMS.